EGO.Summarium

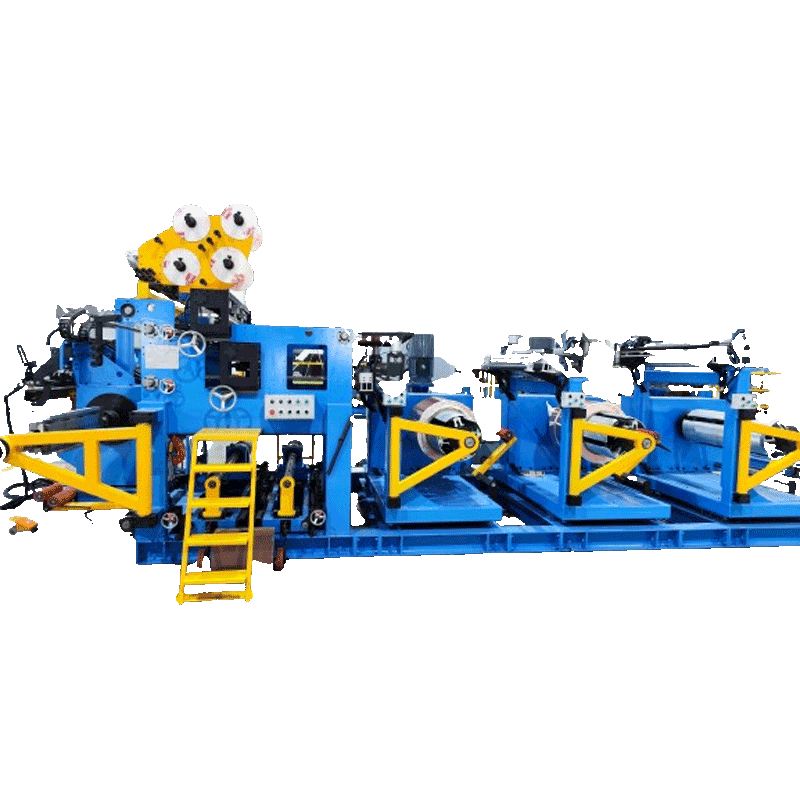

LV ffoyle coil utitur alia crassitudine aeris vel aluminii foil sicut conductor, genus band amplissimum materia velitationis sicut iacuit velit, in ffoyle tortuosus completus machinae genus flexuosum, coil volvulum formans.

Hoc instrumentum etiam ad similem flexum electricae industriae spiram applicari potest.

Machina modum moderandi PLC adoptat cum notis automationis altae.

Ⅱ.Compositio et functio Equipment

BR/III-MC Tres-Laer Foil Machina curva includit

I) Foil de torretur fabrica II) curva fabrica III) Stratum Nulla decoctionem fabrica

4) Praecipua partes frame 5) Welding fabrica 6) Deburring et purgatio fabrica

7) Exsectio fabrica 8) Finis velit deridens fabrica etc

III. Pelagus Technical Parametri

| Sr# | ITEM | SPECIFICATION |

| 1 | Coil | Processus range |

| 1.1 | Axialis longitudo | 250~1100 mm |

| 1.2 | Longitudo axialis (include plumbum | 400~1760 mm (cum plumbo RH 16 inch, LH 10inch) |

| 1.3 | Diameter exterior (Max) | Φ1000 |

| 1.4 | Coil forma | Circum / cylindricum / rectangulum / coil pondus ≤2000KG |

| 1.5 | Centrum altitudo | 850mm |

| 2 | Coil Material | Claua aeris, aluminium foil |

| 2.1 | Latitudo | 250—1100 mm |

| 2.2 | Crassitudo (Max) (Summa crassitudo) | Aeris foil: 0.3~2.5mm Aluminium foil: 0.4~3mm |

| 2.3 | Coil diametri interioris | Φ400-500mm |

| 2.4 | Coil diametri exterioris (Max) | φ1000mm |

| De-coiler | Independentes tres occidere |

| 3.1 | Longitudo cylindri portantes | 1150 mm |

| 3.2 | Expansion range offerens cylindrici | Φ380~φ520 |

| 3.3 | Facultatem afferens (Max) | 2000KG |

| 3.4 | Vis expansion (Electric) | 0~15000N Expansion vis stepless Novifacta |

| 3.5 | Modus offset correctionis | Manual/Automatic |

| Machina curva |

|

| 4.1 | Curva celeritas | 0~20 rpm |

| 4.2 | Aureus (Max) | ≥ 8000N·M |

| 4.3 | Curvis potentia | 20-30 KW |

| 4.4 | Celeritas imperium modo | Frequentia conversionis celeritas incauta moderatio |

| 4.5 | Curvis hastile | 50*90mm |

| 5 | Welding fabrica |

|

| 5.1 | modus welding | TIG |

| 5.2 | Conducendi bar glutino crassitudine | ≤ 20mm |

| 5.3 | celeritas glutino | Auto-celeritas imperium 0~1m / min stepless celeritas ordinatione |

| 6 | Secans fabrica |

|

| 6.1 | forma secans | Plumbum Screw secans Disc |

| 6.2 | Celeritas secans | 1.5 m / min |

| 6.3 | Secans longitudinem | 1150mm |

| 7. | accumsan insulatinguncoilmachinam | |

| 7.1 | Nulla velit accumsan hastile installed | 2 sets |

| 7.2 | Nulla volumine accumsan exterioris diametri | ≤φ400 mm |

| 7.3 | Nulla volumine accumsan interiorem diametri | φ76 mm |

| 7.4 | Nulla volumine accumsan accumsan | 250~1150 mm |

| 7.5 | De-coil modum tensio hastile | Genus pneumaticum |

| VIII. | ThefinisNulla uncoiling fabrica |

|

| 8.1 | quantitas | Sinistra dextra inter IV occidere |

| 8.2 | Nulla finis extra diametrum | ≤φ350 mm |

| 8.3 | Nulla diam finis | Φ56 mm |

| 8.4 | Nulla latitudo finis | 10-100mm |

| VIIII. | Rperficiens fabrica (foil alignment) | egoindependent 3 sets |

| 9.1 | Rectificandi modus | Systema photoelectricum |

| 9.2 | Rectificandi praecisione | Random ±0 .4 mm 20 strata coil ± 1mm |

| 10. | Electric control system | PLC automatic modus |

| 10.1 | Numerus digitals | IV-digital(0-9999.9) |

| 10.2 | Operatio interface | Color tactus screen |

| 11. | Other |

|

| 11.1 | Nulla cutting fabrica | Configurationis duo |

| 11.2 | ffoyle materia margines deburring fabrica | Configurationis tria |

| 11.3 | ffoyle materia purgatio fabrica | Configurationis tria |

| 11.4 | Welding aqua piscinae refrigerandum | configuratione |

| 11.5 | Potestas Supple | 3-PH;380V/50HZ (Potest nativus) |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com